CUSTOM SCREEN PRINTING

WHY WOULD I NEED SCREEN PRINTING?

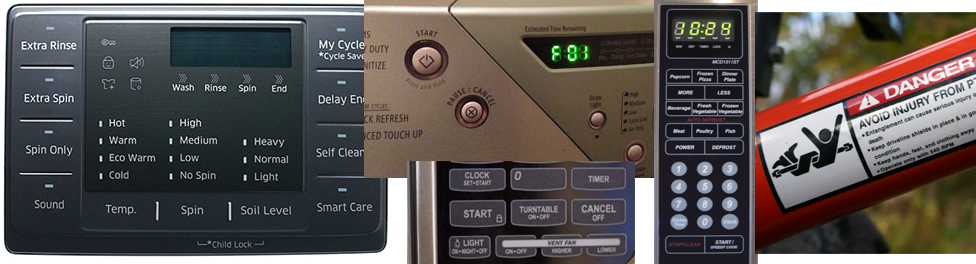

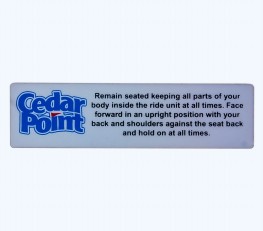

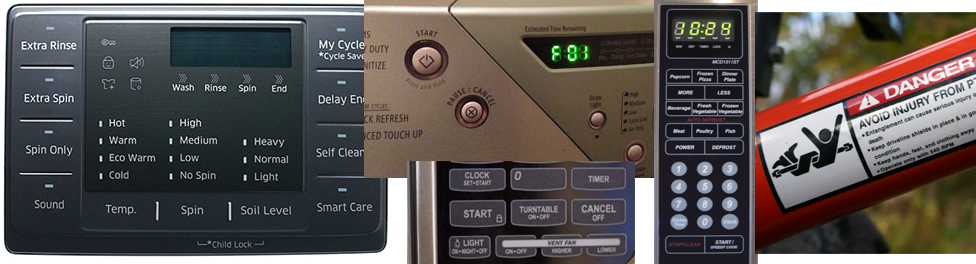

If you need graphics on a product you most likely need screen printing. Take a look around your world, graphics are on everything, signs, labels, electronics. If you need graphics you need screenprinting. Below are a few examples of everyday things we take for granted that use screenprinting to communicate instructions, warnings and functions to users everyehere. Not only do the graphics need to be crisp ans concise, they also need to hold up to long term use in everyday conditions. Here at NVU we have some unique processes that we use specially for prototype and low run parts to help get your product off the ground. Sometimes its better to start with a fully functional prototype that can be handed off to a larger factory before launch/tooling. Often we transition from the prototype part supplier to the main factory supplier on printed parts, sometimes we hand off the tech specs and processes, its up to you as to how the process will proceed.

NEW! Our print quote guide. Click the image for a PDF print guide for files to be sent over.

HOW DO WE DO IT?-

For more information on the printing process check out our tech blog for a detailed photo journal on the complete screenprinting technique we use to print custom and production parts. CLICK HERE.

Its a great place to start of you are looking for print service and not quite sure where to begin. The more you know about the process, the farther ahead you will be when it comes to designing your graphics in a print-friendly manner. Here at NVU we can use your design or come up with one for you based on your input. Parts can be flat (preferred) formed, laser or die cut.

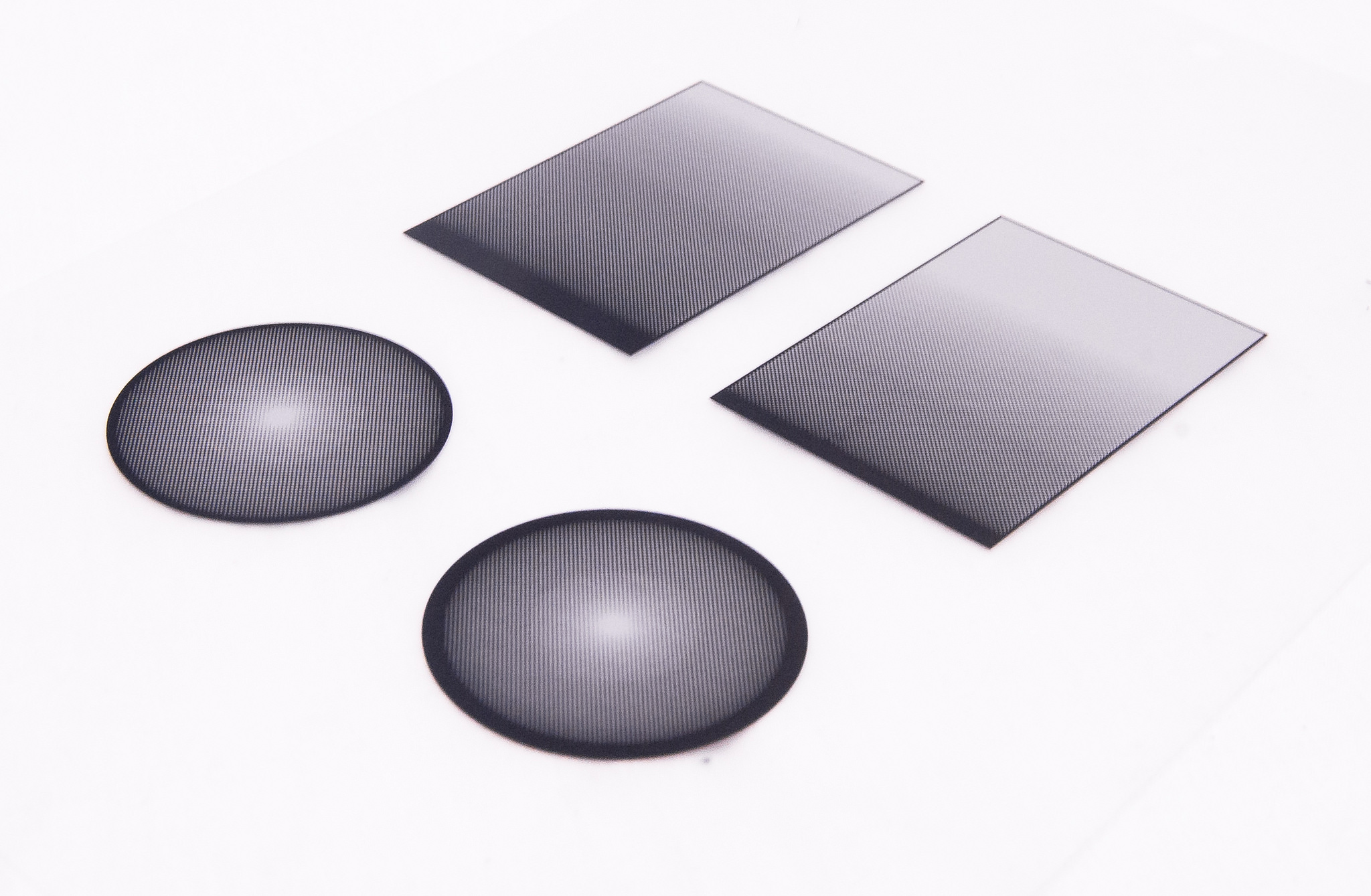

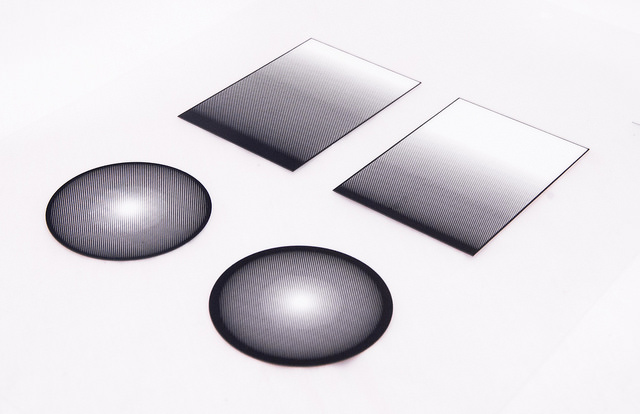

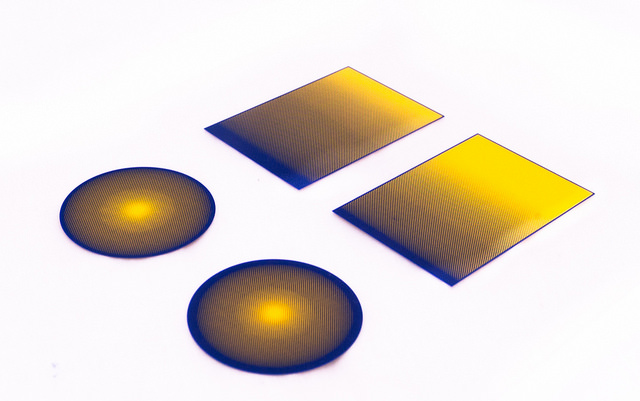

Below: a few parts to wet your appetite.

FROM 1-1,000 WE CAN HELP BRING YOUR PROJECT TO LIFE

Metal is a popular option for a part that is rigid and may require mechanical fastening (rivets, screws, etc). We generally use an enamel ink that is basically paint. This bonds to the surface well and dries to a very durable surface that is resistant to most chemicals. We can print on bare metal or painted. Multiple colors can also be applied.

We can print on your parts or we can supply them. Based on quantities, the parts can be stamped out with a punch die (requires tooling), laser cut or water jet, just ask what is the best option for you.

The designs at right can also be printed on other substrates; if you have any questions feel free to call.

PLASTICS By far plastics are the most popular material we print due to the ease of use, durability and wide range of finishes.

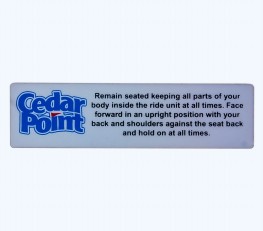

At right are some examples of signage generated for a client who needed something that not only was durable, but also self-adhesive, and light able. NVU stocks a wide range of material thicknesses and textures (more on that later, see below).

This set is printed on .015" polycarbonate with a velvet finish. This texture is very good for high use areas where contact is inevitable. This project is printed 2nd surface (back side) so that when applied, the ink is not accessible but beneath the polycarbonate.

BELOW images of the above signs backlit. Not only can the image bee seen well during the day but also is available as light able

Generally we use a 3M adhesive backing for application of polycarbonate prints. This product has a stability and good lamination up to 180C. This is the same product we use for OE and military applications

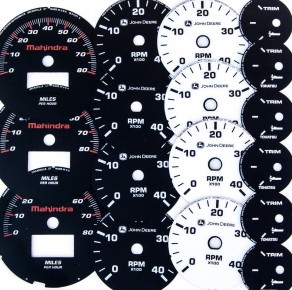

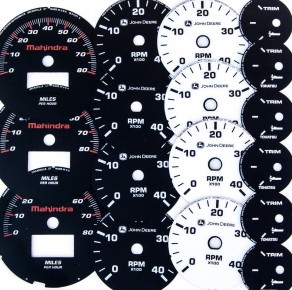

CLUSTER OVERLAYS

NVU not only is the only instrument manufacturer in the US that designs and screen prints all dials in house; we also provide cluster overlays and dials for a wide range of OE customers.

Our exclusive no-tool system allows for any size and shape without the need for costly cutting dies or punches

LIGHT COMPENSATIONDepending on the application and requirements of the project, NVU can light compensate backlit graphics for an even lit look at night. The degree of "hot spots" is dependent on the placement of lighting bulbs and other elements inside the unit that may shadow areas of the dials.

There are a wide range of ways to deal with light diffusion, most commonly a layer of white or colored inks are applied to the back of the dial to strategically darken areas. The downfall is the lit area will only be as bright as the darkest portion.

The top image shows before light compensating, bottom after

There are also other diffusion techniques that can be used like a layer of white plastic or lenses that would diffuse light above the lamp or LED

NVU EXCLUSIVE SYSTEM MAKES SET-UP EASY AND COST EFFECTIVE

Multiple parts and projects can be set up at one time, printed and cut in one lot. This avoids additional setting up of projects and ensures all parts in the same lot are constsient.

The multi-layer dials at right are for 5 instruments and we were able to print all 8 pieces of different shapes in one run and cut at the same time. Traditonal processes woudl require running 8 different dials individually and 5 die cut tools. One run and no tools!

METALS

Bare or painted, it all depends on what the end result you desire.

You can supply parts or NVU can custom cut as needed, volumes and thickness will determine the best route to cut parts and paint for you if needed.

Any thickness, as long as its flat and we can lift it!

POLYCARBONATE

A great choice for most applications and available in a wide range of textures and thicknesses (see below)

NVU can print light able or non-light able polycarbonate parts that are mechanically or laminate attached.

Display at right has laser cut backing and printed polycarbonate labels for a long-lasting finish that customers can touch and can be easily cleaned as needed.

POLYCARBONATE TEXTURES

Gloss: High gloss on both sides. This type of material is used often on microwave oven and washing machine control touch pads

PROS: Provides a rich, high gloss look.

CONS: Scratches and flaws are easily visible. |

|

Matte: Very fine texture provides a matte appearance. This is most often used on instrument dials and the texture is not usually visible.

PROS: Hides scratches and is washable. Some chemical resistance

CONS: While scratch resistant, not as durable as velvet finish |

|

Velvet: Coarse texture has a quality look with durable finish. This material is most often used on control pads that are outside like fuel pumps. You may also see this on instrument panels with a texture.

PROS: Very durable and chemical resistant. Resists and hides scratches very well. Easy to clean.

CONS: Texture may be too rough for some applications visually, personal taste. Recommended for high handling or outdoor use |

|

ACRYLIC

Clear or colored, we have plastic suppliers with virtually and color and thickness. Clear acrylic/plexi can be printed on either side

PROCESSES-

For more information on the printing process check out ouyr tech blog for a detailed photo journal on the complete screenprinting technique we use to print custom and production parts. CLICK HERE

ARTWORK:

We can generate artwork for you at an hourly rate if you do not have a designer available. If you have artwork prepared, we can separate it for you. We require artwork to be in a vector format, that is best for changing over to films when separating for films. We can work with some rasterized graphice but they will need to be high resolution (300DPI min) and be very few colors.

ARTWORK BEST PRACTICES TO MAKE YOUR PROJECT A SUCCESS:

Setting up your graphics in a matter that is condusive to screenprinting wil save you time, money and headaches down the line. Here are some general guidelines:

Screenprinted graphics are solid colors (see gradients below)

Colors need to be separated by some space, we ask for at leats 2-3 pt between colors

Each color must be a separate block or grapohic, refrain from masks or compond paths that cannot be dis-assembled.

Sending over flies in an AI format:

-Save as Ai 10, this format, this will reduce the graphics to the native format and eliminate masks generated by higher Illustrator versions

-Keep different colors on different layers, including having the cut file on a separate layer.

Ready for a quote? send it in via our RFQ form HERE

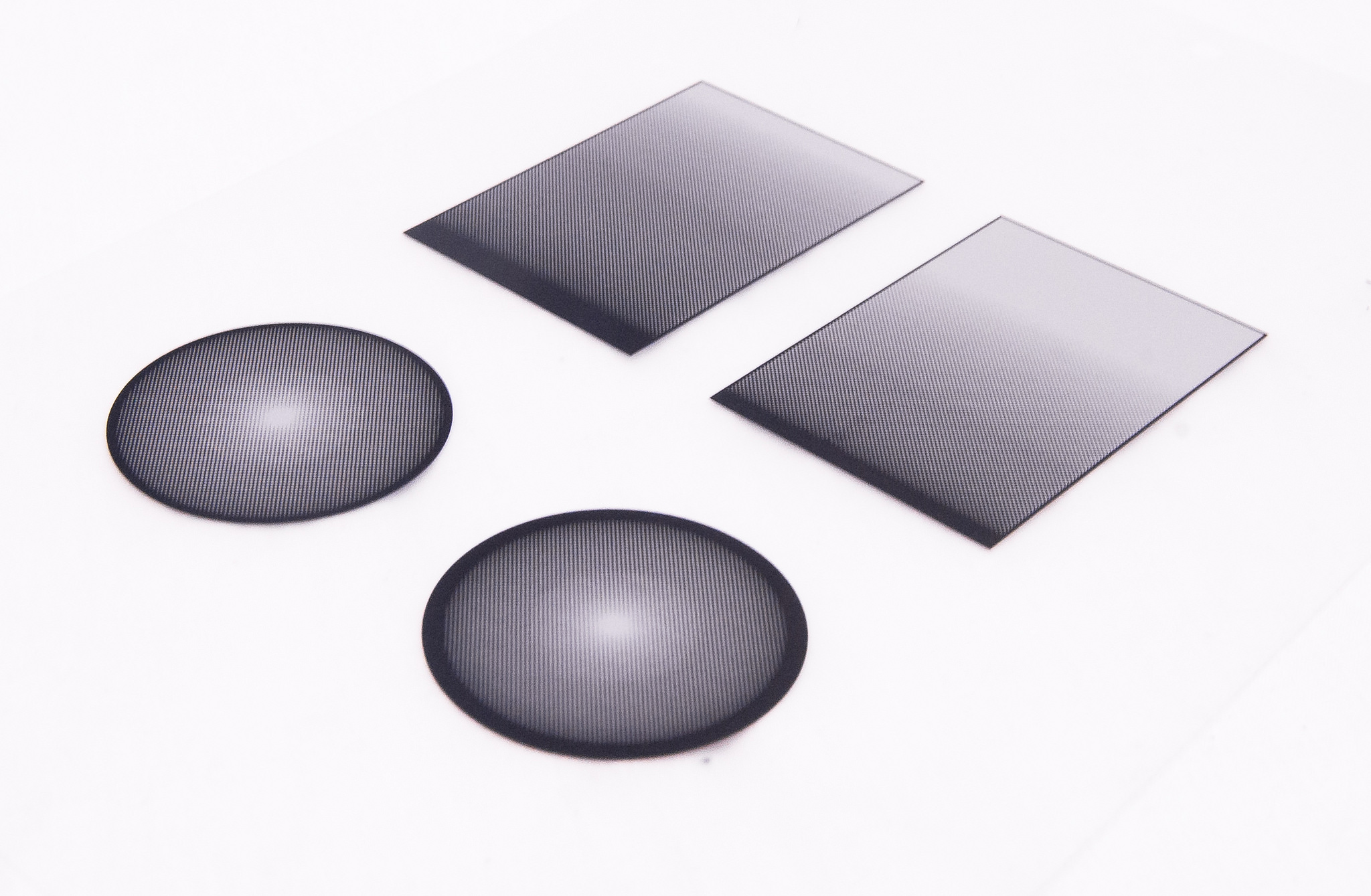

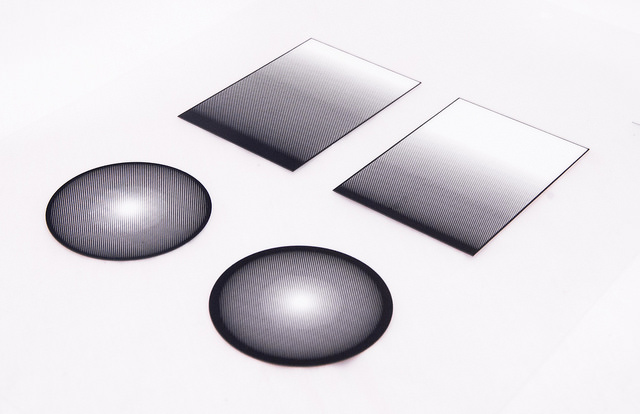

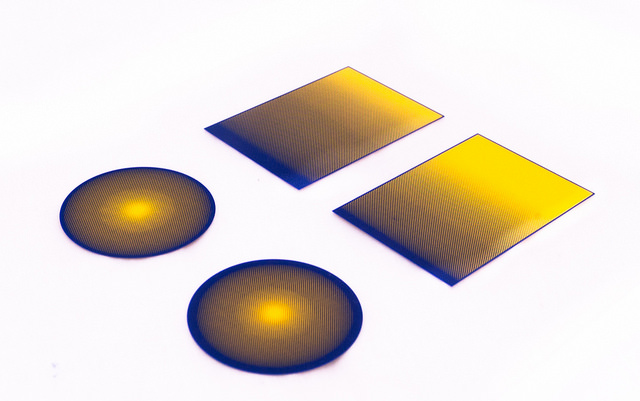

GRADIENTS

Yes gradients can be done but it requires that a halftone be turned into a series of dots. We do this during the ripping process through our printer, there are programs however that can do this pre-press. The one hitch is its best to have the halftone color printed on top of a base layer, 2 colors in each area. Below are some examples. Click on the images and a new window will open to our flickr page wherer you can zoom in even more.

Yes we can adjust the dot pattern to be larger/smaller, larger will yeild a more consistant result, better on long runs, smaller can take longer and is OK for smaller one offs. We can also adjust the pattern to be seamless and smooth, its just a matter of spending the time to print out films at various DPI and trying them out until we have the best result for each project.