SMALL BLOCK FORD INSTALLATIONS

NVU TECH DEPT. on 14th Mar 2025

The Small Block Ford is still extremely popular in builds. No reason to "upgrade" if it works right?

SPEEDOMETER:

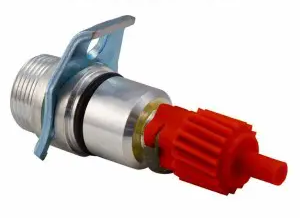

FORD/TREMEC SPEED SENDER 99006-04

APPLICATIONS:

- 1968–1981 FMX—A hybrid of the FX and MX

- 1964–1981 C4

- Most small block V8 powered cars of the 1960s and 1970s in the North American market

- 1966–1996 C61974–1989 C3—Light-duty, smaller than the C4

- Most big-block V8 powered cars/trucks of the 1960s and 1970s in the North American market, All F-series trucks without O/D, 80 thru 96 (97 For F250HD, F350, and F-Superduty models)

- 1982–1986 C5—Improved C4, with a lock-up converter

- 1985–1994 A4LD—C3 with overdrive

- 1989–1998 E4OD—C6 with overdrive

Tremec Aftermarket

Any transmission that uses a Ford style cable

These setups are for vehicles that have a mechanical cable driving your speedometer. A gear is required to spin the speed sender once inserted (not included). This is usually still on the end of your old cable, you can re-use it, no problem. The tooth count of the gear is not important as the speedometer will be calibrated to your specific vehicle. Don't forget the clip that holds the gear on!

Tremec transmissions: This setup has 2 configurations available. The first one is an OE-style 2-wire speed sender. This generally has a very weak signal and on occasions its difficult to get a good, consistent reading. The second option is to use the mechanical drive port and install our 99006-04 speed sender and be done with it. You can also us our 99009-04 GPS speed sender. We have a good video on the subject right here:

Remove the old cable from the transmission by removing the bolt that clamps the hold down in. The cable should pull out. It might be a little stubborn if its been in there for 30-40 years!

Add the gear back on and install in the transmission. It may be a little tight as the sealing ring is needed to ensure a leak-free fit. A little lube helps.

OE STYLE 2 WIRE SPEED SENDERS

NVU speedometers are compatible with most OE speed senders. What's great about these is they are already there-nothing to buy!

******

This section will cover connecting directly to the speed sender. This is an option only when your PCM does not require a signal. LS swaps and aftermarket controllers will need the signal to operate properly, from there the PCM or controller will send out a signal to the speedometer. Check out our TECH BLOG and TECH VIDEOS for even more info on those types of setups.

******

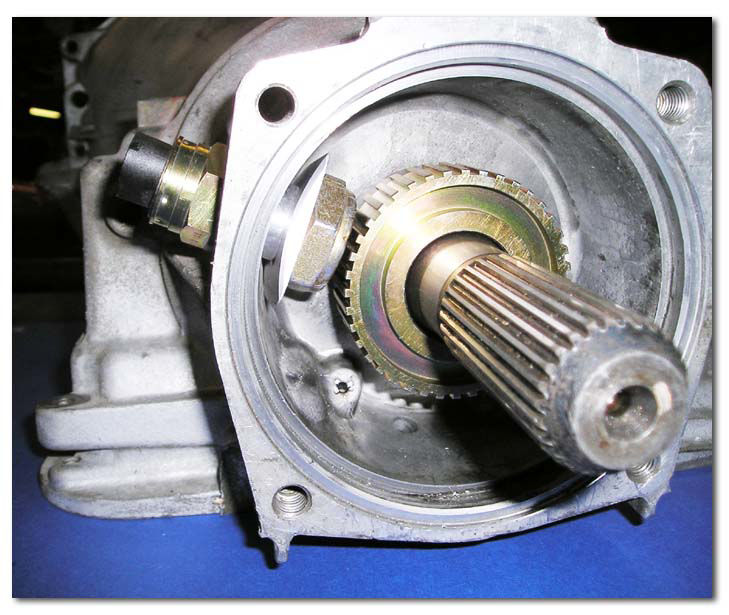

This type of sender, while more widely used in the 90s and early 2000's is simple and reliable. It generates its own power and sends an AC sinewave signal to the speedometer by teeth spinning past a coil with 2 wires. The sender requires one wire to be grounded, and the other is the signal. The wires can be reversed, and the same result will work just fine due to the fact that the sender waveform is a simple sinewave.

The downside is that due to the sender generating its own power by the speed of the reluctor wheel (teeth) it can often lead to a weak signal at low speeds. this is often seen when a speedometer will not operate until a certain speed, say 25-30 MPH. NVU electronic programmable speedometers have built-in sensitivity settings that can be changed to suit your signal strength. ONLY NVU speedometers have this capability removing the need for converters, boxes or additional equipment. One other disadvantage to this type of sender is the signal cannot be split to send pluses to multiple devices such as speedometer and cruise control.

This is what it looks like inside:

Typical OE style speed sender:

WIRING:

One wire is ground (keep the ground short for a good signal)

The other wire is the signal, this goes to the orange wire on the speedometer.

You cannot split the signal on 2-wire senders, if needed, a splitter may be required for cruise control.

Calibration is easy, we have a simple video here:

GPS SPEED SENDER 99010-04

Don't feel like messing around with all of that? No problem, our GPS speed sender has been out most popular accessory for over a decade! 1000s of them are on the road right now!

TACHOMETER

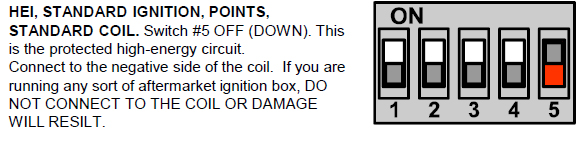

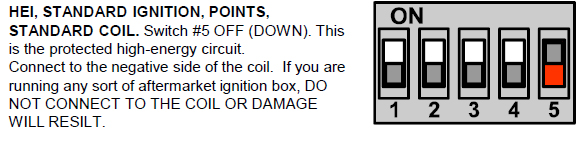

TRADITIONAL COIL INSTALLATION:

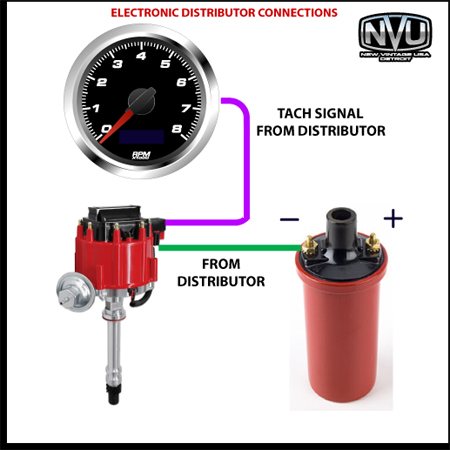

This setup uses a traditional distributor/coil. The tach reads from the negative side of the coil. The green is shown for clarity and may be a different color in your application.

ELETCRONIC IGNITION DISTRIBUTOR/HEI PERTRONIX (SEE NOTE)

Most distributors built after 1976 use an electronic module instead of points and have a TACH OUTPUT right on the distributor. This output generally has a 12V square wave signal, It may be "high" or "low" voltage. Either way it is designed for a tachometer to see.

PERTRONIX SYETEMS: We recommend using a 1K resistor inline to prevent damage to the tachometer circuit.

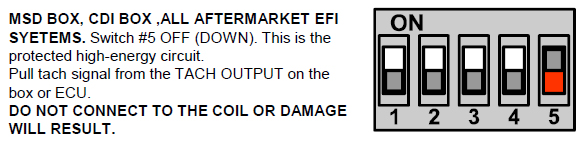

"MSD" BOXES AND OTHER IGNITION CONTROLLERS

This is probably the most popular ignition setup for aftermarket ignitions. The "MSD" box is a Multiple Spark Discharge system (MSD) which can generate up to 60,000 sparks (pulses) per spark plug firing. EVERY system like this has a tach output right on the box. It is either a 12V or 5V square wave signal designed to be clean for a tach to read. Notice the box has power and ground going to the coil. This creates a high voltage feedback that will damage the tachometer input. This is exactly why a separate output is used.

We looked up some different aftermarket ignition tach schematics and they are all over the place. Take a look HERE

WATER TEMPERATURE AND OIL PRESSURE SENDERS

For the best results we recommend using liquid type sealant on the threads, avoid Teflon that may cause grounding and longevity issues.

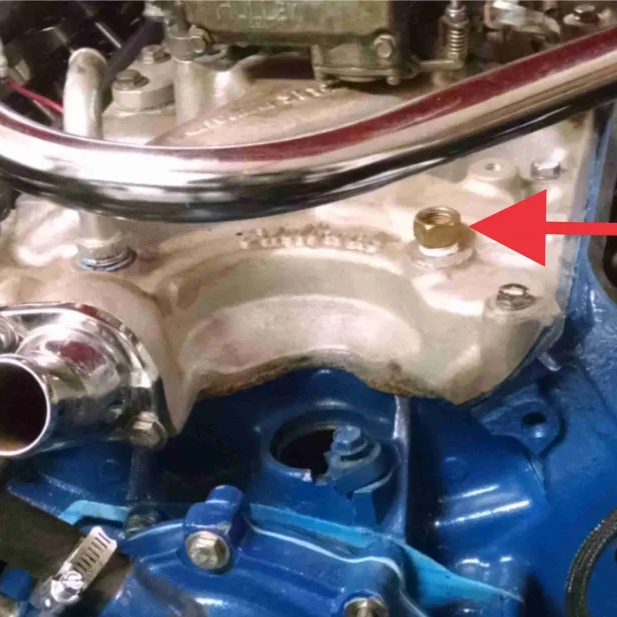

We get this call all the time and people just can't believe that Ford used a big, long extension for their oil pressure senders. Take a look at the driver side in front of the oil filter, that long extension is the pressure port, here is a stock setup:

Here is a "homemade" setup, it is doing the same job. You can get away with a shorter version if you are not using a mechanical pump, not sure why this one is so long.

The temperature sender is generally located in the intake manifold just before the coolant exits via the thermostat and water neck. This can vary based on the manufacturer of the manifold. Make sure the distributor and manifold you use have proper clearance for your sender. Often you may need to use a thermostat /water neck housing with a sender provision. Generally, the thread size is 1/2" NPT but may differ by manifold manufacturer.

VOLTS AND FUEL

VOLTS is internally monitored, and no additional wiring is required.

FUEL LEVEL is read from your fuel sender in the fuel tank. Our Phoenix Platform gauges have fully programmable, dampened fuel gauges that can work on just about any tank/sender. We have a comprehensive article on how to use, set-up and test fuel senders and gauges RIGHT HERE>>>>

You can also check out this video covering the basics ass well